Manufacturer: WEBEN / CEEVER

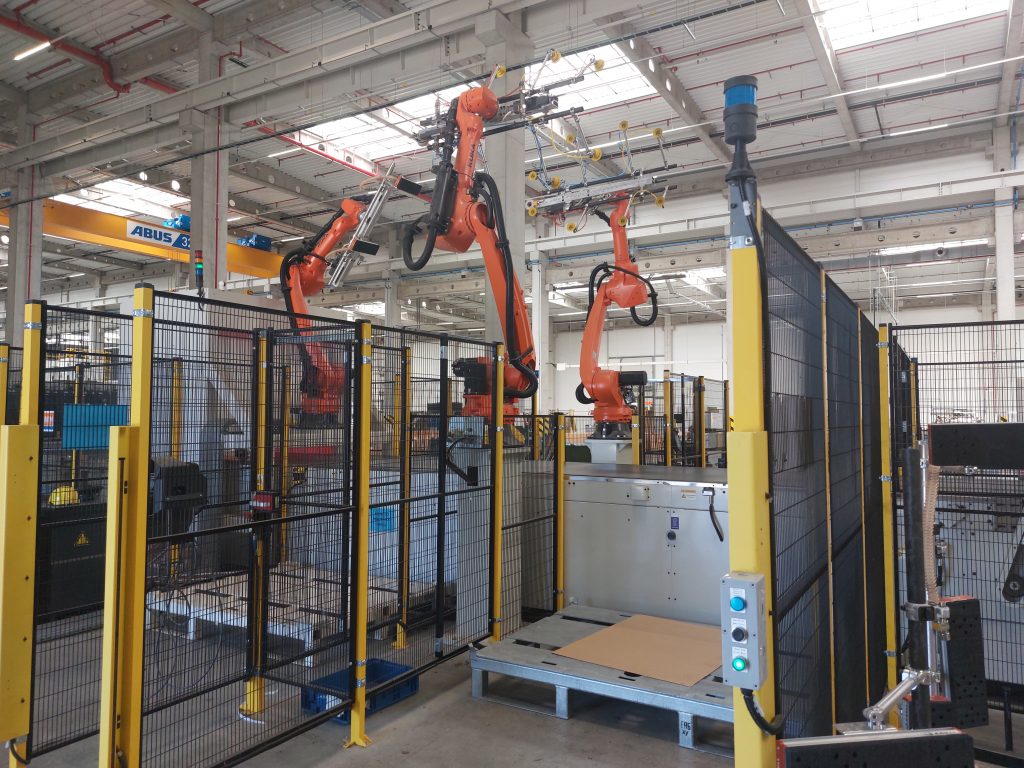

Application: Automated part handling after an upstream press (press not included), washing, drying and quality inspection

Description:

This system is an automated line for transferring parts coming from an upstream press. Robots take the parts, move them through a conveyor transport system into an industrial washing tunnel (wet cleaning) and then through an inspection/measuring station for automated quality control. The overall concept is designed for continuous operation, combining robot handling, washing process, conveyor technology and automatic quality decision (OK/NOK).

Technical Data – Washing Tunnel

Year of manufacture: 2021

Cleaning process: spray-spray water-based cleaning, air blow-off, hot-air drying

Max. workpiece dimensions: length 1400 mm

Max. workpiece dimensions: depth 2000 mm

Max. workpiece dimensions: height 10 mm

Max. workpiece weight: 12 kg

Overall dimensions: width 3000 mm

Overall dimensions: depth 35,500 mm

Overall dimensions: height 3400 mm

Weight (empty): 20,000 kg

Weight (ready for operation): 27,000 kg

Wetted material: stainless steel AISI 304

Wash tank volume: 4000 liters

Wash tank heating: electric 80 kW

Rinse tank volume: 2500 liters

Rinse tank heating: electric 40 kW

Wash pump: 2000 l/min, 6 bar, 30 kW

Rinse pump: 900 l/min, 6 bar, 15 kW

Wash filtration: bag filter, 4 pcs, 100 µm

Drying: electric 48 kW

Power supply: 380–400 V / 50 Hz / 3 Ph + N

Total connected load (washing tunnel): 385 kW

Compressed air automation: 6–8 bar, connection 1/4″

Compressed air blow-off: 6–8 bar, 4 connections, consumption approx. 30,000 Nm³/h, connection 1 1/4″

Technical Data – Robot, Conveyor and Inspection System

Control system: Siemens PLC S7-1500 1517F

HMI: Siemens TP1900 Comfort

Robots: KUKA KR50 R2500 IONTEC with KRC4 (multiple robots in the line)

Conveyor system: multiple conveyor sections / transport zones

Max. conveyor speed: up to 24 m/min

Inspection system: laser measuring unit with automatic OK/NOK evaluation and sorting

Location: EU

PRICE: ON DEMAND